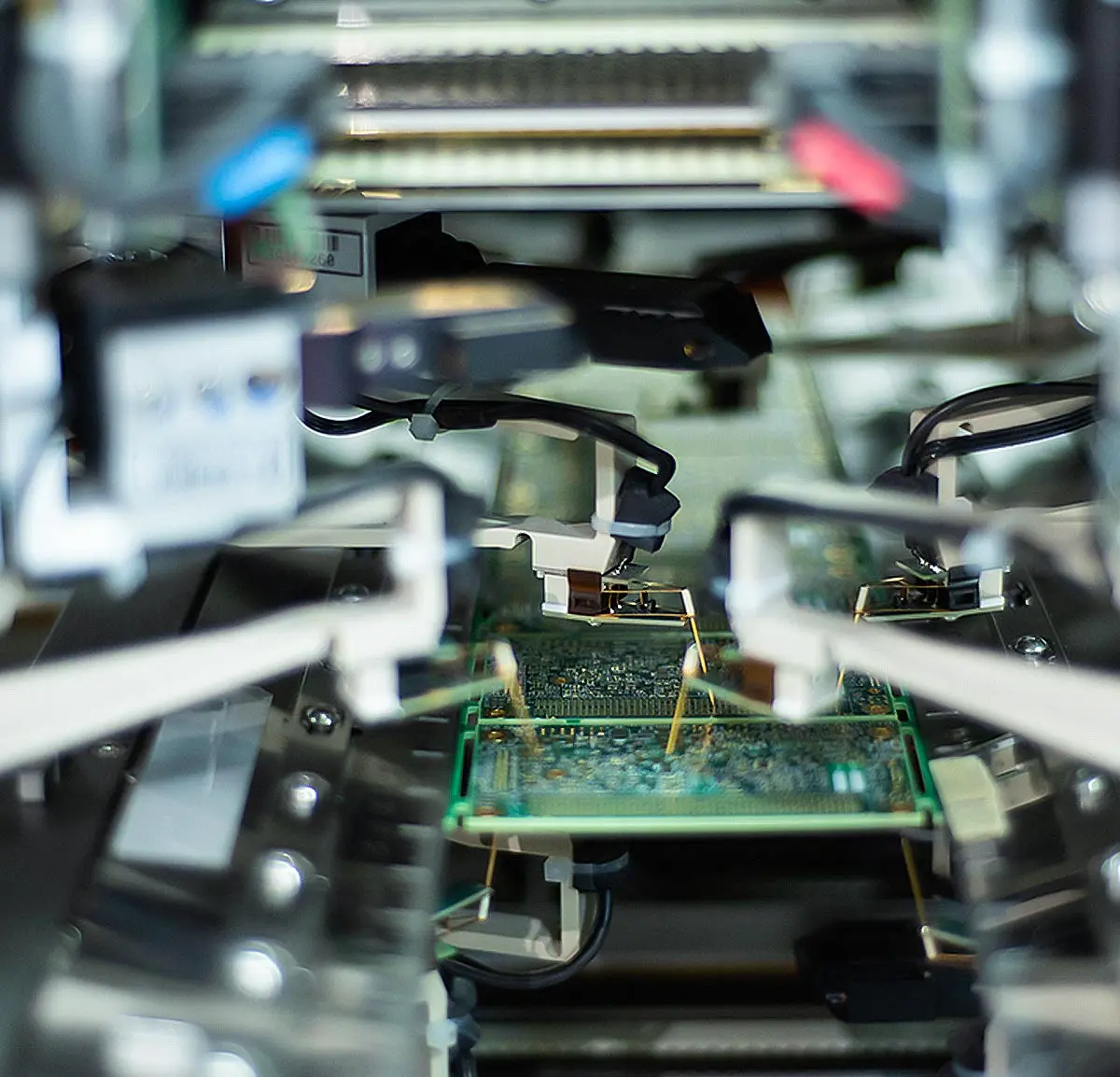

Automated PCB Production Facility

Phase-1 of our factory spans approximately 50,000 square meters, with an additional 60,000 square meters planned for Phase-2. Our team comprises over 600 skilled professionals focused on the design, development, production, and sales of single-layer, double-sided, and multi-layer PCBs. We boast an annual production capacity of 1.4 million square meters, catering extensively to consumer electronics, IoT, industrial control, security, and other sectors.

We have integrated cutting-edge production equipment to guarantee the superior reliability of our products.

To keep pace with the rapid evolution of PCB design and the demand for advanced products, we have recruited top-tier process engineers and invested in state-of-the-art precision drilling equipment, exposure machines, and a three-stage etching process. These advancements have enabled us to achieve industry-leading standards in domestic manufacturing processes.

Presently, we specialize in producing BGA boards with a standard line width and spacing of 3 mil, along with pads as small as 0.25 mil. Our capabilities extend to manufacturing boards ranging from 1 to 40 layers, ensuring both quality and timely delivery.

Get a Quote

Continuing with the description of production equipment

Multi-layer PCB Lamination Equipment

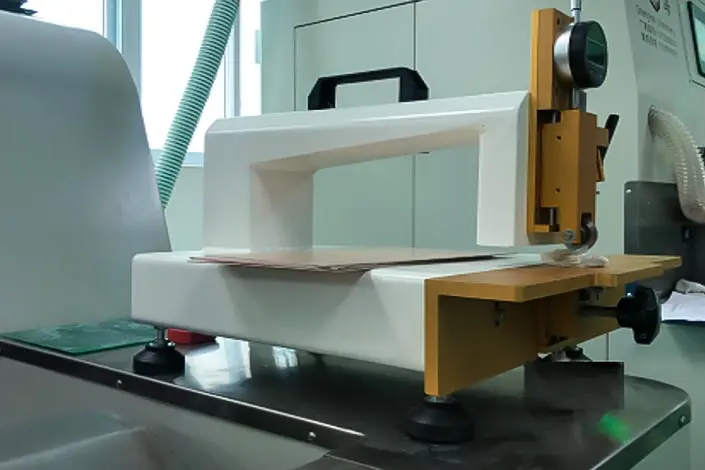

Automated Material Cutting Machinery

Drilling Machine from Taiwan Dongtai

Vertical Plated Through-Hole

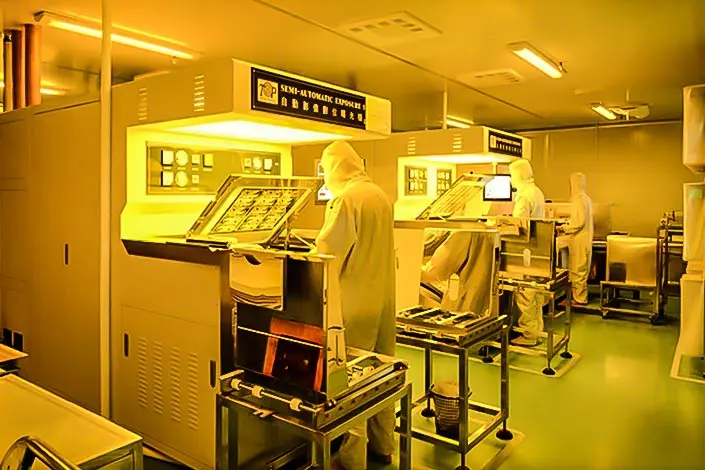

Automatic LDI (Laser Direct Imaging) Exposure System

Taiwan Jingming Electroplating Line specializes in advanced electroplating processes.

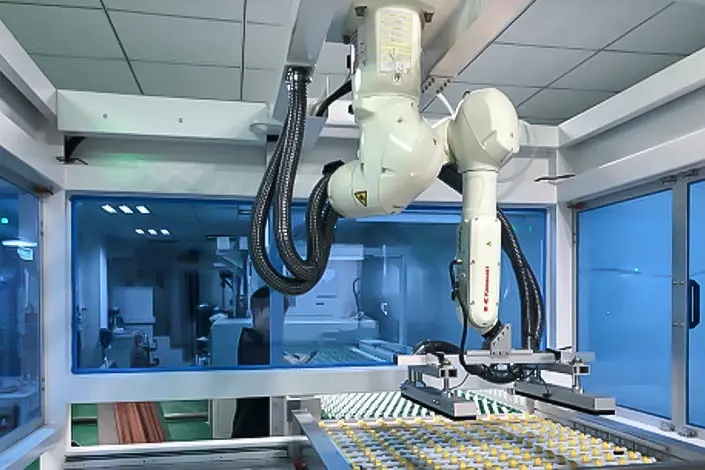

Automatic Arm Robot (Six-Axis Configuration)

Screen Printing Equipment for PCB Manufacturing

CCD Automated Exposure System

Automated Printing Equipment

Computer Numerical Control (CNC) Routing Equipment

Automated Testing System

We contribute to creating a smarter and more beautiful lifestyle.

We contribute to creating a smarter and more beautiful lifestyle.

To keep pace with the fast-evolving demands of PCB design and the shift towards more sophisticated products, we’ve invested in top-tier process engineers, high-end precision drilling equipment, advanced exposure machines, and implemented three-stage etching lines. These enhancements have enabled us to achieve industry-leading domestic standards.

Presently, we specialize in producing BGA boards with a standard line width and spacing of 3 mil, as well as pads as small as 0.25 mil. Our capabilities extend to manufacturing boards ranging from 1 to 40 layers, ensuring consistent quality and reliable delivery.

Get a Quote

Quality Assurance Equipment